Email Us

Can the 200ML disposable spray cup system 2.0 become an efficiency revolutionary in the coating industry?

Why do traditional spray cups always plunge painters into a "cleaning nightmare"?

Last week, a car touch-up paint technician with 15 years of experience complained to me, "Every time I change the color, it takes 20 minutes to disassemble and clean the cups. The paint stains in the nail crevices can't be washed off for three days." This is not an isolated case - the threaded structure of traditional metal spray-painted cups is prone to paint residue, and the repeated use of plastic cups can cause scratches and dirt accumulation on the cup walls. According to statistics, the coating industry wastes over 20 million hours of working time each year due to cleaning cups, which is equivalent to 2,500 workers working non-stop throughout the year.

The Aspaint R&D team, through 3D scanning of the operation habits of over 1,000 painters, found that the pain points were mainly concentrated in two major issues: "complex disassembly and assembly" and "cleaning dead corners". Our unique "one-click ejection cup body" design enables the replacement of the cup body to be done simply by pressing the button with one hand, and the residual paint will fall off along with the entire cup body. In the actual measurement of a large furniture factory, the color-changing time of the painters was shortened from 18 minutes to 90 seconds, and the smoothness inside the cup body reached Ra0.8μm, with the paint residue rate reduced by 92%.

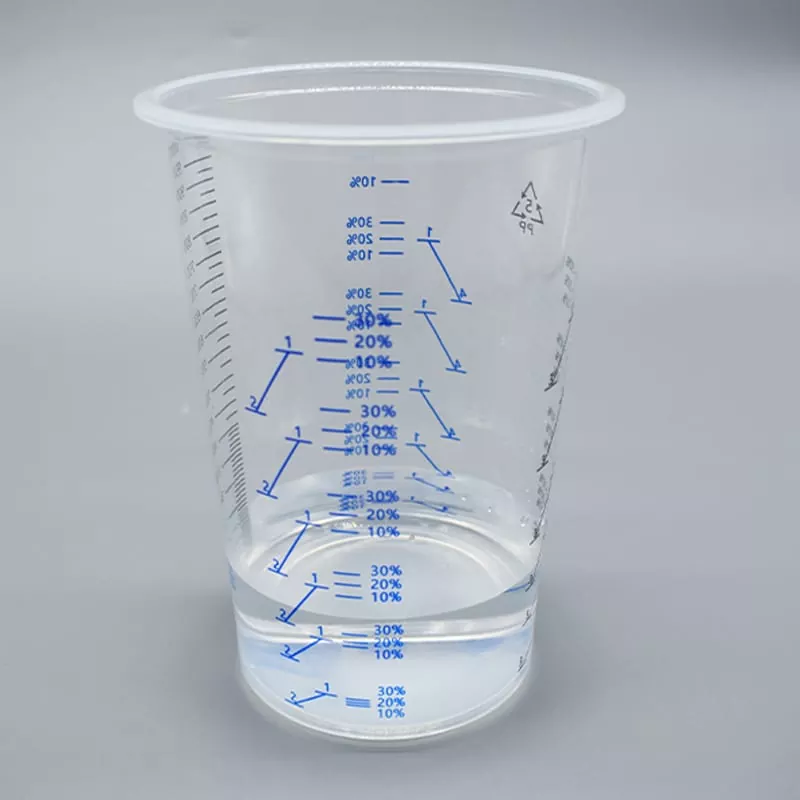

How does a 200ML capacity design solve the "size contradiction"?

"150ml is not enough to spray the entire car door, and 300ml is too heavy, causing hand tremors" - this is the genuine feedback from a supervisor of a new energy vehicle painting line. There is a polarization in the capacity design of traditional spray painting cups: small capacities require frequent replacement, while large capacities increase operational fatigue. Aspaint engineers, through ergonomic simulation analysis, found that 200ml is precisely the golden capacity for one-handed grip - it can not only meet the demand for continuous spraying of 3 square meters of area, but also keep the cup body weight at 280g (including paint), which is 25% less than the 300ml product.

200ml Disposable Paint Cup System 2.0 Core Parameter Table

| Parameter | Traditional Metal Cups Of Aspaint 2.0 System | Traditional Metal Cup | Ordinary Plastic Cup |

|---|---|---|---|

| Capacity | 200ml±3ml | 150-300ml | 200ml |

| Cup Weight (Empty Cup) | 35g | 120g | 50g |

| Paint Residue Rate | ≤8% | ≥35% | ≥25% |

| Applicable Viscosity Range | 15-120DIN·s | 20-100DIN·s | 30-90DIN·s |

| Solvent Resistance | No Deformation After Soaking In Acetone For 72 Hours | Wrinkles In 24 Hours | 48-hour softening |

How can the sealing problem be overcome by the "double insurance structure"?

A certain ship painting company once had protective suits worth 120,000 yuan scrapped due to paint leakage from cups. The fundamental reason was that the single-threaded seal of the traditional cup lid was prone to deformation during high-pressure spraying. Aspaint adopts a double safety design of "pressure balance valve + silicone sealing ring" : when the pressure inside the cup exceeds 0.3MPa, the balance valve automatically releases the pressure. The 360° wraparound silicone ring can withstand a temperature difference of -30℃ to +80℃ without deformation. In the burst test conducted by a third-party laboratory, our product withstood a pressure of 1.2MPa without leakage, which is 2.4 times the industry standard.

Where is the balance point between environmental protection and cost?

"Disposable products = waste of resources?" This is a question raised by a certain environmental protection organization about the coating industry. Aspaint provides the answer with "degradable materials + modular design" : The cup body is made of PLA corn starch-based material, which can be completely degraded within 180 days under industrial composting conditions. The lid and nozzle are made of recycled PP plastic and support 10 cycles of use. Data from a certain electronics factory shows that after adopting the Aspaint system, the annual waste generation per unit of equipment has dropped from 48kg to 12kg, while the cost of consumables has decreased by 18% - because there is no need to purchase cleaning agents or replace sealing rings.

Why is the Aspaint 2.0 system called "the second pair of hands for painters"?

From automotive repair to architectural spraying, from wooden furniture to 3C electronics, Aspaint has provided solutions for coating enterprises in 47 countries around the world. Our products not only pass the SGST certification, but also feature a unique "color paste compatibility database" that can match over 2,000 common types of paints. A certain art painting studio reported: "Previously, color mixing required three attempts and errors. Now, with Aspaint's proportioning guide, it succeeds in one go, and the saved paint is enough to spray five murals."

Our products are highly reliable. If you have any needs, please feel free to contact us at any time. We will be online 24/7 to provide you with efficient solutions.

- How Can a Reusable Paint Mixing Stick Truly Save You Money

- Fill it, lock it, spray it——It's done!

- How to Make Paint Stay on a Plastic Cup?

- Color Changes Can Be Completed In Just Five Seconds - The Innovative Disposable Spray Gun Cup Improves Spraying Efficiency

- Why Should You Use a Disposable Paper Paint Strainer

- What Is The Thread Size Of A Standard Air Spray Gun Adapter

Contact Us

Building 3, Excellence West Coast Financial Plaza, Huangdao District, Qingdao, Shandong, China

Copyright © 2025 Qingdao Aspaint Technology Co., Ltd. All Rights Reserved.