Email Us

What Is an Air Spray Gun Aluminum Adapter and Why Does It Matter for Professional Painting

An Air Spray Gun Aluminum Adapter may look like a small component, but it plays a critical role in ensuring compatibility, stability, and efficiency in professional spray painting systems. From automotive refinishing to industrial coating and woodworking, the right adapter directly impacts paint flow, connection security, and overall spraying accuracy. This in-depth guide explains what an Air Spray Gun Aluminum Adapter is, how it works, why aluminum is the preferred material, and how to choose the right model for your application.

Table of Contents

- What Is an Air Spray Gun Aluminum Adapter?

- Why Is an Air Spray Gun Aluminum Adapter So Important?

- Why Aluminum Is the Ideal Material for Spray Gun Adapters

- Common Applications of Air Spray Gun Aluminum Adapters

- How an Air Spray Gun Aluminum Adapter Improves Painting Efficiency

- Key Specifications to Consider When Choosing an Adapter

- Comparison Table: Aluminum Adapter vs Other Materials

- Installation and Maintenance Best Practices

- Why Professionals Trust Aspaint Air Spray Gun Aluminum Adapters

- Frequently Asked Questions

1. What Is an Air Spray Gun Aluminum Adapter?

An Air Spray Gun Aluminum Adapter is a precision-machined connector designed to link an air spray gun with a paint cup, hose, or auxiliary accessory. Its main function is to ensure a secure, airtight connection between components that may have different thread standards or interface designs.

In professional painting systems, adapters are not optional accessories—they are structural components that directly affect spray consistency, leakage prevention, and operator safety. Aluminum adapters are especially favored due to their balance of strength, weight, and corrosion resistance.

2. Why Is an Air Spray Gun Aluminum Adapter So Important?

The importance of an Air Spray Gun Aluminum Adapter becomes obvious when compatibility issues arise. Spray guns and paint cups often come from different manufacturers, each with unique thread types and dimensions. Without a properly designed adapter:

- Air leaks may occur, reducing spray pressure

- Paint flow can become unstable or inconsistent

- Threads may wear out prematurely

- Operator efficiency and finish quality decline

A high-quality aluminum adapter ensures system integrity, improves spraying precision, and extends the lifespan of both the spray gun and the paint cup.

3. Why Aluminum Is the Ideal Material for Spray Gun Adapters

Aluminum has become the industry standard material for spray gun adapters—and for good reason. Compared with plastic or steel alternatives, aluminum offers a unique combination of properties that suit professional environments.

- Lightweight: Reduces hand fatigue during long spraying sessions

- Corrosion Resistance: Ideal for solvent-based and water-based coatings

- High Strength-to-Weight Ratio: Maintains durability without bulk

- Precision Machinability: Ensures tight tolerances and leak-free connections

An Air Spray Gun Aluminum Adapter manufactured with CNC machining and proper surface treatment provides consistent performance even under high-pressure conditions.

4. Common Applications of Air Spray Gun Aluminum Adapters

Air Spray Gun Aluminum Adapters are widely used across multiple industries, including:

- Automotive refinishing and detailing

- Industrial metal coating

- Furniture and woodworking finishing

- Marine and aerospace painting

- DIY and custom paint workshops

In each application, the adapter ensures reliable paint delivery and compatibility between tools, making it an indispensable component of any spray system.

5. How an Air Spray Gun Aluminum Adapter Improves Painting Efficiency

Efficiency in painting is not just about speed—it is about minimizing waste, rework, and downtime. A well-designed Air Spray Gun Aluminum Adapter contributes in several ways:

- Prevents air and paint leakage

- Maintains stable spray pressure

- Allows quick switching between paint cups

- Reduces cleaning time caused by improper connections

Over time, these advantages translate into lower material costs and more consistent surface finishes.

6. Key Specifications to Consider When Choosing an Adapter

Before selecting an Air Spray Gun Aluminum Adapter, professionals should evaluate the following parameters:

- Thread type (male/female, metric/imperial)

- Compatibility with spray gun and paint cup

- Surface treatment (anodized, polished, raw aluminum)

- Pressure rating

- Weight and ergonomic design

Reliable suppliers such as Aspaint provide detailed specifications to ensure correct selection and long-term performance.

7. Comparison Table: Aluminum Adapter vs Other Materials

| Material | Weight | Durability | Corrosion Resistance | Professional Suitability |

|---|---|---|---|---|

| Aluminum | Light | High | Excellent | ★★★★★ |

| Plastic | Very Light | Low | Moderate | ★★ |

| Steel | Heavy | Very High | Low | ★★★ |

8. Installation and Maintenance Best Practices

To maximize the lifespan of your Air Spray Gun Aluminum Adapter:

- Always clean threads before installation

- Avoid over-tightening to prevent thread damage

- Inspect seals and O-rings regularly

- Store adapters in a dry, dust-free environment

Proper care ensures consistent performance and prevents unnecessary downtime.

9. Why Professionals Trust Aspaint Air Spray Gun Aluminum Adapters

Aspaint has built a strong reputation for manufacturing precision-engineered spray system components. Their Air Spray Gun Aluminum Adapter products are designed with:

- High-precision CNC machining

- Strict quality control standards

- Wide compatibility across global spray gun brands

- Professional-grade aluminum materials

By focusing on real-world application needs, Aspaint delivers adapters that professionals can rely on for consistent, long-term use.

Frequently Asked Questions (FAQ)

Is an Air Spray Gun Aluminum Adapter universal?

Not all adapters are universal. Thread type and size must match both the spray gun and paint cup.

Can aluminum adapters handle high-pressure spraying?

Yes, high-quality aluminum adapters are designed to withstand professional air pressure levels without deformation.

How often should an adapter be replaced?

With proper maintenance, an aluminum adapter can last for years. Replacement is usually only needed if threads are damaged.

Does an adapter affect spray pattern quality?

Indirectly, yes. A secure, leak-free adapter ensures stable pressure, which helps maintain a consistent spray pattern.

In professional painting, every component matters. Choosing the right Air Spray Gun Aluminum Adapter is a small decision that delivers significant performance benefits. If you are looking for reliable, precision-made adapters backed by manufacturing expertise, Aspaint is ready to support your needs. For product details, technical guidance, or custom solutions, contact us today and upgrade your spray system with confidence.

- What Is a Paint Mixing Stick and Why Does It Matter in Professional Painting

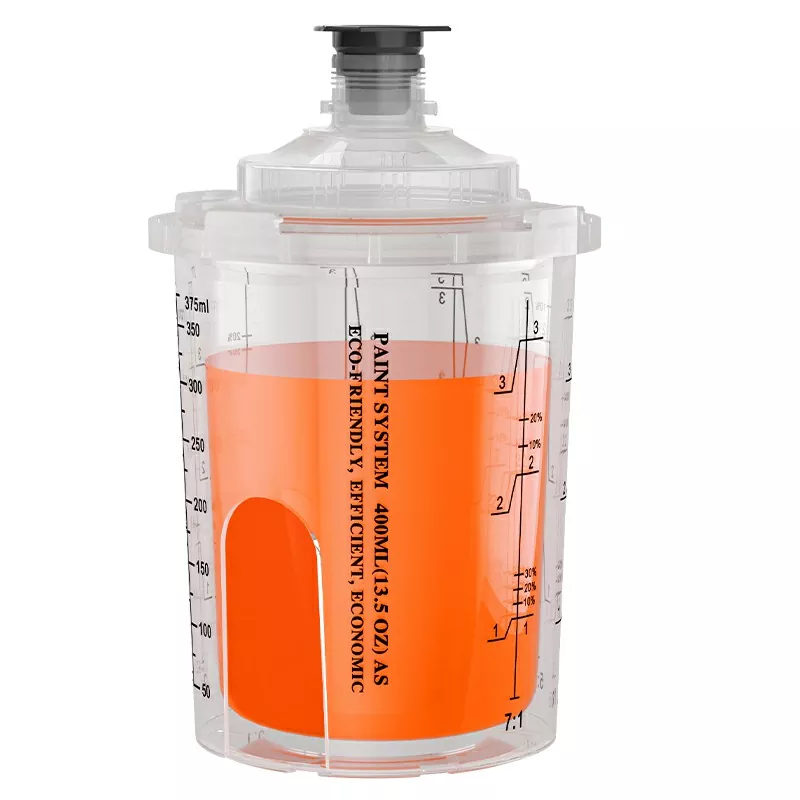

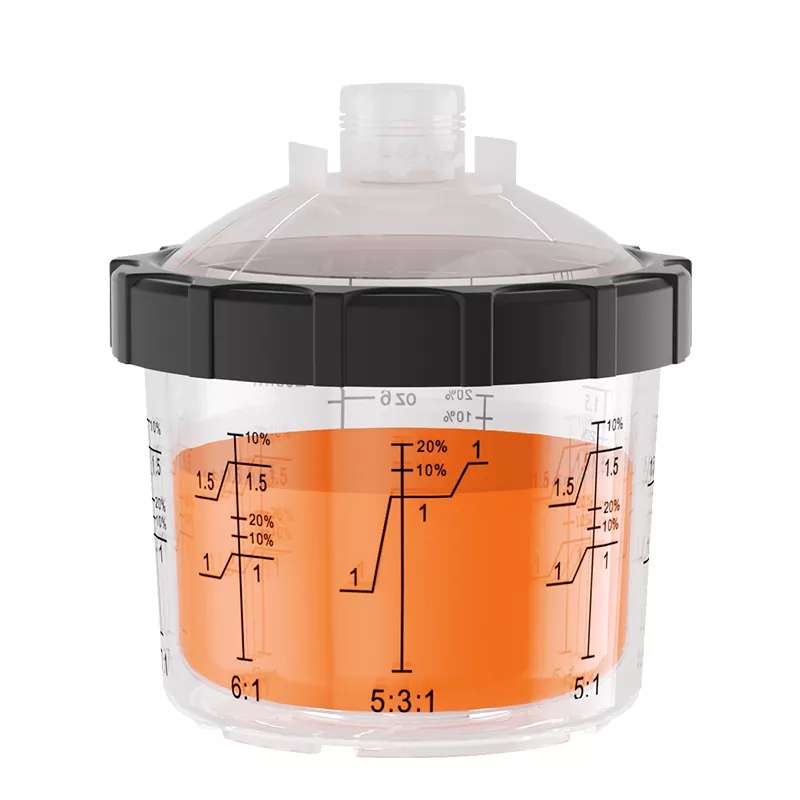

- What Makes a High-Performance Paint Mixing Cup Essential for Professional Coating Works

- What Are the Best Air Spray Gun Adapters for Automotive Painting

- What Are the Benefits of Using a Paper Paint Strainer for Paint Mixing

- How Can a Reusable Paint Mixing Stick Truly Save You Money

- Fill it, lock it, spray it——It's done!

Contact Us

Building 3, Excellence West Coast Financial Plaza, Huangdao District, Qingdao, Shandong, China

Copyright © 2025 Qingdao Aspaint Technology Co., Ltd. All Rights Reserved.