Email Us

Which factories use paint mixing cups most frequently

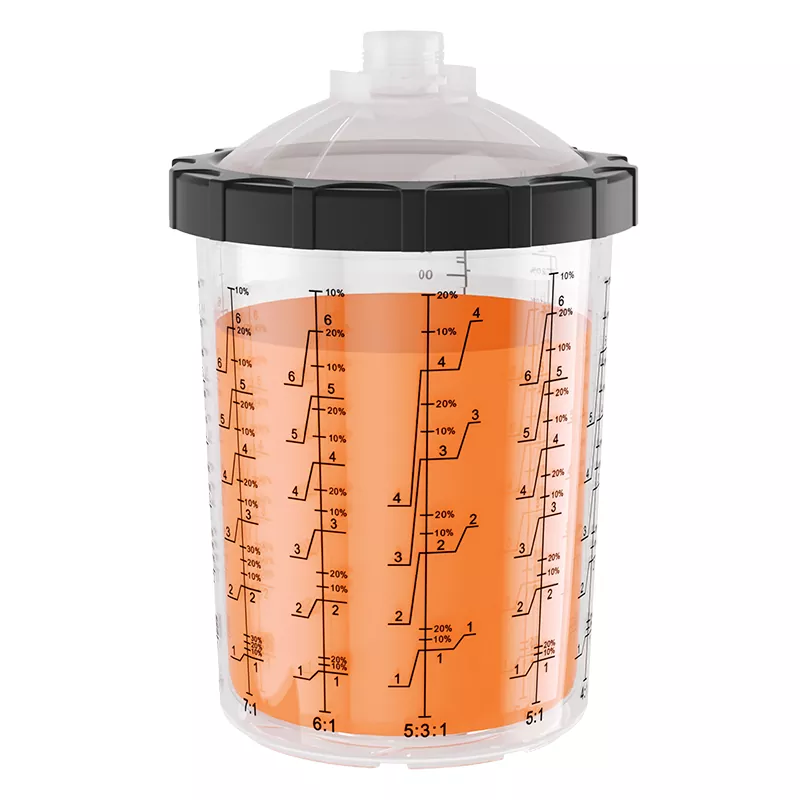

The powerful performance of the disposable spray gun cup system is mainly reflected in the following aspects:

Improved operating efficiency

The disposable design eliminates the steps of cleaning the traditional mixing cup and replacing the filter paper, shortening the spray preparation time by about 40%. Its closed structure can complete the entire process of paint mixing, filtering and spraying directly on the spray gun, reducing the time spent on process switching.

Anti-pollution closed-loop system

The combination of the built-in filter and the sealing cover can isolate external dust and prevent the paint from being contaminated during the spraying process. The system supports the use of the spray gun inverted, and the paint surface can be kept clean even when spraying complex curved surfaces.

Optimized resource utilization

Through precise control of the paint ratio and atomization effect, the solvent consumption is reduced by 15%-20%, and the amount of waste generated is reduced by more than 30%. With the electrostatic adsorption technology, the paint utilization rate can reach more than 90%, far exceeding the 60-70% level of traditional spraying6.

Process compatibility expansion

The modular adapter design makes it compatible with mainstream spray gun models, which can not only match the high-speed atomization requirements of the electrostatic rotary cup, but also support the refined spraying process of the external mixing spray gun. For example, in automotive spraying, it can simultaneously meet the uniform coverage of the color paint layer and the glossiness requirements of the clear coat layer.

The system integrates filtering, mixing and application functions, while improving the coating quality, and realizes cross-domain adaptation from industrial sheet metal spraying to precision device coating.

- How Can a Reusable Paint Mixing Stick Truly Save You Money

- Fill it, lock it, spray it——It's done!

- How to Make Paint Stay on a Plastic Cup?

- Color Changes Can Be Completed In Just Five Seconds - The Innovative Disposable Spray Gun Cup Improves Spraying Efficiency

- Why Should You Use a Disposable Paper Paint Strainer

- What Is The Thread Size Of A Standard Air Spray Gun Adapter

Contact Us

Building 3, Excellence West Coast Financial Plaza, Huangdao District, Qingdao, Shandong, China

Copyright © 2025 Qingdao Aspaint Technology Co., Ltd. All Rights Reserved.